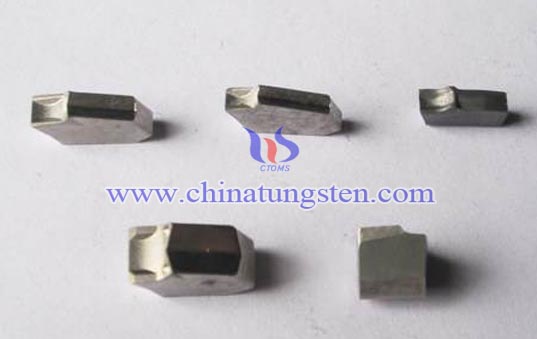

tungsten carbide inserts composition and quality measuree

Tungsten carbide is currently the main cutting tool material. So far, various grades of tungsten carbide inserts at home and abroad are included in its composition, density, bending strength and stiffness to demonstrate its main properties. And one of the density, bending strength and hardness depends on the composition and content of tungsten carbide.

Density and hardness values measured of tungsten carbide inserts is an effective way to determine inserts real ingredient content and performance quality index. Tungsten carbide inserts density greater nominal range or greater difference between the measured density inserts, the inserts of the ingredients of such differences and performance are also greater.

Tungsten carbide inserts performance depends on its composition, content than its level of manufacturing process. Different components made of different content than varieties and grades. Such as YG6 and YG8 that the difference lies in the content of Co, Co weight ratio of 2W / 0, although Co of YG6 and YT15 are the same weight, after adding TiC, TiC and WC due to density difference of 3.18 times, resulting YT15 the actual content of the inserts Co 23% lower than the YG6, one of the main factors affecting the YT15 hardness and flexural strength. Clearly, Co content changes affect the performance of the Co-based alloy is most sensitive. Nominal density tungsten carbide inserts is an important index to judge the quality of the inserts, which has a nominal density range is larger, the content range of the actual composition of the inserts is also greater, the difference between the performance of such inserts are greater.

HRA values for density and tungsten carbide inserts detection and judgment are important quality indicators to measure and evaluate its ingredients and performance. inserts hardness values reflect not only the composition ratio of the inserts, but also reflects the inserts porosity, grain size distribution and uniformity of quality problems. Therefore, the determination of the density and the HRA can not only determine the value of the inserts ingredients and quality, but also the highly automated processing difficult materials processing and cutting inserts for this test was to determine the main indicators of selected pieces. According to the above classification of various grades of ingredients and the impact on performance and grades.