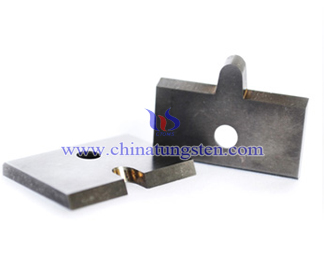

gradient structure tungsten carbide inserts

Gradient structure tungsten carbide inserts carbide gradient composition or tissue distribution. Gradient structure tungsten carbide composition by gradient structure or organization while achieving good performance alloys, such as alloy can be given at the same time high hardness and high toughness. So as to solve the contradiction of traditional tungsten carbide hardness and toughness. TGradient structure tungsten carbide inserts overall performance was significantly higher than the average performance of conventional alloys.

In order to obtain high performance tungsten carbide inserts, the alloy may be processed using a gradient, the gradient-treated alloy after processing region lack toughness cubic carbides and carbonitrides are formed in the surface region, the high binder content of the corresponding in the nominal content of the binder matrix. On this alloy coating to obtain gradient cemented carbide coatings. When cracks are formed when the coating is extended to the gradient zone toughness, due to its good ductility and toughness, can absorb energy during crack propagation, it is possible to effectively prevent the expansion of the crack to the inside of the alloy, to improve the use of tungsten carbide inserts performance.

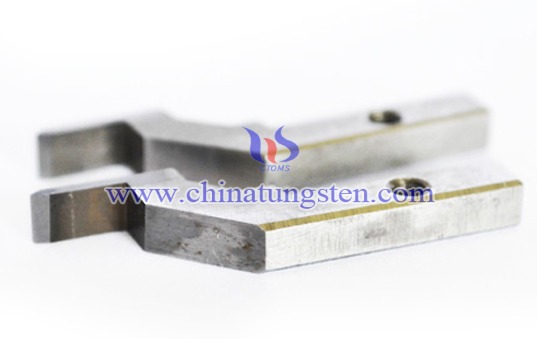

With the increase of cobalt content in the matrix, sintered base strength is increased, hardness is reduced, the magnetic force decreases, while the density is reduced to improve the magnetic saturation. And with the increase in the cobalt matrix phase content, gradient cemented carbide substrate structure more obvious, the thicker the layer thickness gradient.

Same cobalt content of the matrix, the more pre-magnetic and magnetic saturation after burning decreases after gradient sintering and coating; hardness increased slightly; strength continues to improve, especially after the matrix alloy coating significantly increased strength. In the substrate and coating composition the same situation, there are better coated gradient structure tungsten carbide inserts than those without coated gradient structure tungsten carbide inserts.